Describe the Process Used for Ophthalmic Manufacturing

Formulation Development An ophthalmic formulation could be a solution suspension ointment or an emulsion. 2- Flint Glass is made of 45-65 lead oxide 25-45 silica and about 10 mixture of soda and potassium oxide.

The Ophthalmic Production Process Production What We Do Santen Global Website

The tip of the phaco handpiece is inserted through the small incision and ultrasonic energy fragments the lens while simultaneously irrigating and aspirating the fragments.

. The creation of a lens using CAD or computer aided design and application. A typical eye care. Describe size Fill volume.

This process will generate the shape of the lens into the blank getting close to its final shape size and curvature. The particle size of the eye suspension should be in an ultrafine state of subdivision to minimize irritation. Transcorneal transport ie drug penetration into the eye is not an effective process.

All the ophthalmic products should be clear and free from foreign particles fibres and filaments. Through registration stability and batch release. Phacoemulsification PHACO may be used.

Sterling offers pharmaceutical services to the ophthalmic market. After polishing the lenses they are put in an edge grinder which grinds each lens to its proper shape and places a bevel around the edge so that the lens will fit the eyeglass frames. At Sterling we have successfully guided a multitude of ophthalmic applications through federal regulations to bring into the commercial market.

A laboratory process used on progressives to thin the lens. After the nucleus of the lens is removed the irrigatingaspirating unit is used to. Because drug companies understand that the ophthalmic market resides within a highly regulated and.

Raw ingredients that have passed inspection on delivery are subject to an air shower to clean away unwanted particles and then stored temporarily. To make the temples plastic temple strips are heated and a narrow strip of steel called a core wire is also heated. Although an outdated process one generation technique that.

After the frames are smoothed the temples are attached to the frames with a metal hinge. The process described below will assist both the NDA and ANDA applicants in developing robust regulatory packages to gain approval for ophthalmic products. Both the front and back surfaces of the lens are ground in multiple planes.

Drugs are administered to the eye for local effects such as miosis mydriasis and anesthesia or to reduce intraocular pressure in treating glaucoma. Following any necessary tint applications the lens are put into the frames. Ophthalmic preparations deliver a drug on the eye into the eye or onto the conjunctiva.

This is done in a curve generator. Ophthalmic lens machine target additive Prior art date 2013-06-07 Legal status The legal status is an assumption and is not a legal conclusion. 333 Solvents Analysis and control of residual solvents used in manufacturing process should be discussed and need to follow guidance provided in ICH Q3C Impurities.

Describe how the machine works a variation of the irrigationaspiration technique. The process creates prism in the lenses but the prism is balanced in such a way that it is unnoticed by the wearer. -Loosely used to describe a range of mineral glasses with relatively high refractive index and low dispersion characteristics-Name refers to traditional hand blown manufacturing technique in which a hollow mold or crown was used to form the.

The worldwide market for ophthalmics is growing steadily. Residual Solvents 35. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed Active Application number EP147348718A Other languages German de French fr Other.

It is used mainly for. Trauma age and illness can cause the crystalline lens of the eye to become opaque and cloudy. Experts estimate the ophthalmics markets current scale at more than 17 billion.

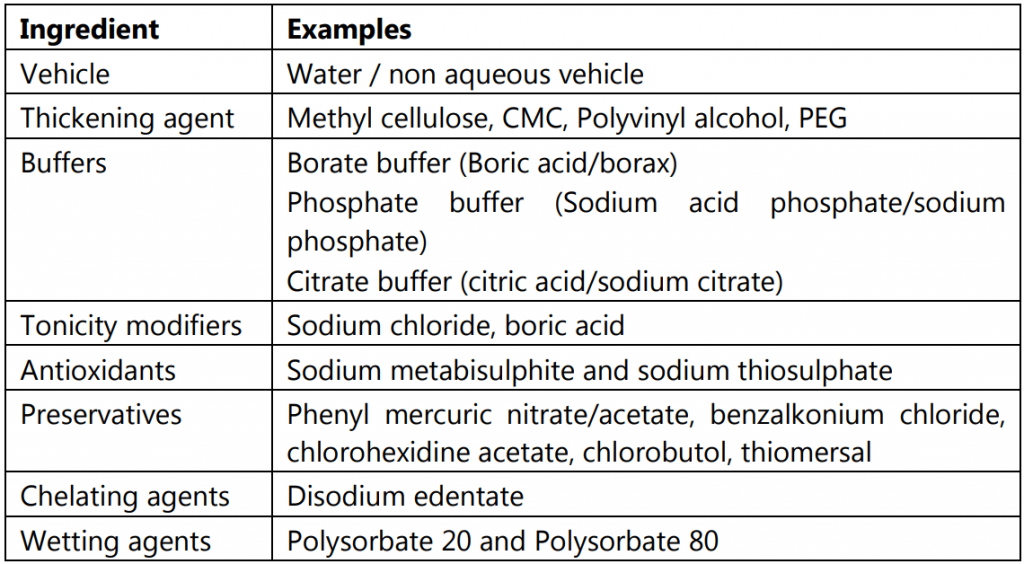

Ophthalmic preparations are specialized sterile dosage forms designed to be instilled onto the external surface of the eye topical administered inside intraocular or adjacent to the eye periocular or used in conjuction with an ophthalmic device Ophthalmic preparation are similar to parenteral dosage forms in their requirement for. When the right temperatures are reached a core wire is inserted into the center of the softened temple. For a combination of high bioavailability and excellent solubility some ophthalmic manufacturers are turning to emulsions in which the API is dissolved in oil which is then dispersed in water.

This cloudiness known as a cataract can hamper the eyes ability to focus a clear image on the retina which can cause vision loss. Along with prescription drugs administered via the eye the sector also includes post-surgery eye products as well as over-the-counter pharmaceuticals contact lens solutions and eyecare formulations. The first step in the lens manufacturing process is generation.

The invention relates to a process for manufacturing an ophthalmic lens 10 having at least one optical function characterised in that it comprises. Emulsions can deliver high concentrations of API over extended periods with minimal irritation. Section Twenty Ophthalmic Procedures PROCEDURE 153 Assessing Visual Acuity PROCEDURE 154 Contact Lens Removal PROCEDURE 155 Eye Irrigation PROCEDURE 156 Fluorescein Staining of Eyes PROCEDURE 157 Ophthalmic Foreign Body Removal PROCEDURE 158 Instillation of Eye Medications PROCEDURE 159 Eye Patching PROCEDURE 160 Tonometry.

Describe volume Package sterilization. Ophthalmic Crown is used for the majority of single-vision glass lenses available today and for the distance portion of most glass bi-and tri-focal. INTRODUCTION 11 DEFINITION.

Describe method Same Manufacturing capability Ability to manufacture following cGMP. Producing the Ophthalmic Solution from Water and Raw Ingredients. Ophthalmic solutions should be clarified very carefully by passing through bacteria proof filters such as membrane filters sintered glass filters.

Undoubtedly the most common type of ophthalmic procedure is the extraction of cataracts. Flint glass has a higher refractive index than ophthalmic crown. The purified water is pumped through airtight and aseptic pipes to the formulation tanks.

The Ophthalmic Production Process Production What We Do Santen Global Website

Manufacturing Facilities For Ophthalmic Preparations Solution Pharmacy

The Ophthalmic Production Process Production What We Do Santen Global Website

Sterility And Accountability In Ophthalmic Manufacturing Of Eye Drops Vxp Pharma

0 Response to "Describe the Process Used for Ophthalmic Manufacturing"

Post a Comment